New Products

Tire repairs materials

expand_moreexpand_lessWeights for wheel balancing

expand_moreexpand_lessValves

expand_moreexpand_lessConsumables

expand_moreexpand_lessImpact sockets

expand_moreexpand_lessTools

expand_moreexpand_lessTPMS

expand_moreexpand_lessCar air conditioning

expand_moreexpand_lessCompressors and pneumatics

expand_moreexpand_lessWorkshop equipment

expand_moreexpand_lessAccessories for Workshop Equipment

Recommended

Outlet

Brands

expand_moreexpand_less

Sales abroad is limited. Please contact us if interested.

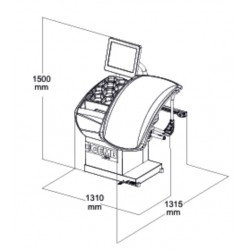

The new ER95 has been designed to be extremely efficient and fast. In a single measurement cycle of just 6.4 seconds, without any intervention from the operator, it is capable of automatically detecting the wheel dimensions and correction plans, and providing a clear and precise indication of the counterweight placement, whether adhesive or clip-on, for balancing correction.

Ergonomic design

The ErgoFast range of wheel balancers has been developed to offer the operator the best possible working conditions. Every tool in a handy position, total access to internal part of rim, all accessories within reach and touch screen are only but a few of the advantages developed for our end users.

3D Laser Scan

– Touchless wheel distance and diameter measuring system which, combined with the external LA sonar for width measurement, detects with 3D precision the dimensions of any profile, even the most complex; no intervention of the operator.

– Advanced technology that speeds up the dimensions reading process without penalizing reliability and precision.

– Brighter laser pointer that grants an extreme accuracy during correction thanks to a clear indication of the application point for stick-on weights.

– Greatest robustness for a long lasting usage. No moving parts are exposed, risks of damages are reduced

– Easy maintenance

OPB: One plane balancing

OPB (One Plane Balancing), eliminates both static and dynamic unbalance with a single counterweight, indicating the exact position to apply the weight inside the rim. The balancer automatically detects if it is possible to correct both unbalances with only one weight, and activates OPB program (One Plane Balancing). A real revolution in wheel balancing. OPB saves you time and money while maximizing your productivity.

AutoAdaptive Mode

The innovative tolerance calculation system AutoAdaptive Mode is based on the evaluation of the residual imbalance limit value corresponding to an acceptable perceived vibration. For each wheel that is balanced, the software AutoAdaptive Mode detects weight and dimensions and calculates the tolerance value that will cancel any vibration perceived on the steering wheel. AutoAdaptive Mode grants the highest comfort when driving, and together with OPB Program, saves balancing time.

New automatic positioning system

The new electromagnetic brake on the DC motor ensures a doubled speed of automatic positioning and instant wheel locking at the weight application point.

LED light

The ER95 is equipped with a built-in LED light designed to illuminate the work area inside the wheel, ensuring better visibility and precision during the placement of counterweights.

EMS Sonar to measure the wheel eccentricity

Through high precision sensors, EMS Sonar (Eccentricity Measurement System) is able to detect variations in the distance between wheel centre and its external edges during rotation, allowing them to be corrected those irregularities that would make the vehicle less safe.

HubMatch

HubMatch detects the unbalance as well as the highest point of the wheel (1st harmonics), and displays it on-screen to enable mounting of wheel on vehicle so that simply matching mechanical clearances when positioning the rim on the hub will eliminate the eccentricity.

STANDARD ACCESSORIES

In 1952 Cemb created the cone adapters for balancing machines and since then the company continued developing and producing high precision centering systems for any type of wheel. Cemb does not recommend the use of non-original adapters on its balancing machines.

SE KIT - Ring, quick locking sleeve SE2, SE spacer

4 CONES KIT - Ø 45÷110 mm, pincer-hammer and 60 g

Width gauge

Single phase power supply

- 230V/1ph/50 hz

- 115V/1ph/60 Hz

Max. absorbed power 0,15 kW

Balancing speed 100 rpm

Measurement spin time for 15 kg (33 lb) wheel 4.7 s

Measurement uncertainty 0,5 g

Avarage noise < 70 dB (A)

Rim width setting range 1.5” ÷ 20” / 40 ÷ 510 mm

Rim diameter setting range 10” ÷ 30” / 265 ÷ 765 mm

Min./Max. compressed air pressure

- 7 ÷ 10 kg/cm2 / ~ 0.7 ÷ 1 MPa

- ~ 7 ÷ 10 bar / ~ 105 ÷ 145 psi

Max. wheel weight < 75 kg

Machine weight 170 kg